Alloy C276 Forgings and ASME SB564 Hastelloy Flanges Suppliers

Stockist of Nickel Alloy EN - Nimo16cr15w Forged, Plate And WNR 2.4819 Blind Flange

Hastelloy Flanges

Hastelloy C276 Flanges

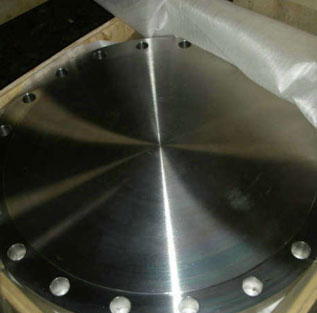

ASTM B564 UNS N10276 Blind Flange

Table of Content

- Hastelloy Flanges Specification Chart

- Various Types of Hastelloy C276 Flanges

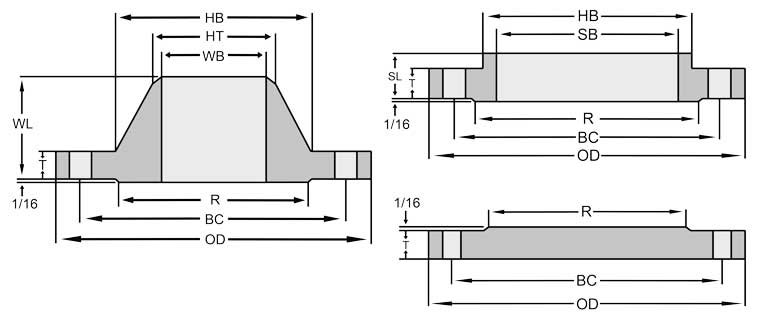

- Dimension of ASTM B564 UNS N10276 Blind Flange

- Nickel Alloy C276 Slip on Flanges Size in MM

- Hastelloy C276 Forging Equivalent

- Rating of EN - Nimo16cr15w Pipe Flanges

- Alloy 276 Weld Neck Flange Prices

- WNR 2.4819 Forged Flange Properties

- Composition Standard of UNS N10276 Plate Flange

- Alloy C276 Flanges Weight

Hastelloy Flanges Specification Chart

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Standards | ASTM, ASME Flange, ANSI Flange, DIN Flange, EN Flange, BS Flange etc. |

| Specifications | ASTM B564 / ASME SB 564 |

| Size | 1 / 2” to 36″ |

| Class | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Grade | Hastelloy C276– UNS No. N10276 |

| Our Hastelloy C276 Flange conforms to NACE MR0175/ISO 15156 | |

Various Types of Hastelloy C276 Flanges

UNS N10276 DIN 2.4819 Hastelloy C276 Blind Flange DIN2527 PN6-PN100 DN10-DN1000

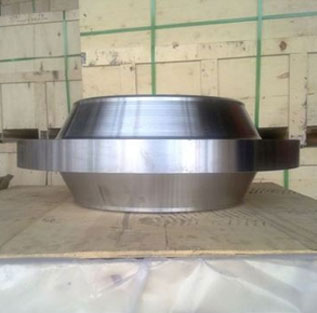

ASTM B564 Hastelloy C276 Lap Joint Flange

Hastelloy C276 Anchor Flange

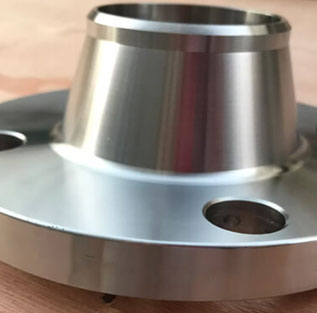

Hastelloy c276 UNS N10276 welding neck WN flange

UNS N10276 C276 Flange 1 1/2" Class 600 SO RF Forged Flange

Hastelloy c276 Plate Flange

Hastelloy C276 Socket Welding SW Flange

Hastelloy c276 B622 Nickel Alloy Steel WN RF Flange

Dimension of ASTM B564 UNS N10276 Blind Flange

| Nominal S | Outside Diame | Min. Thickn | RF D | No. of Bolt Ho | Diameter of Ho | Bolt Cir | SO Bore | * WN Bore | Dia. Hub B | Dia. Hub | SO | WN |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 33 | 9 | 1 | 5 | 88 | 1 | 7 | 3 | ** | 5 0 | 3 | 2 | 4 |

| 44 | 11 | 1 | 6 | 88 | 1 | 9 25 | 4 | ** | 6 | 4 | 2 | 4 |

| 55 | 13 | 2 | 7 | 88 | 1 | 11 0 | 5 | ** | 7 | 5 | 3 | 5 |

| 66 | 15 | 2 | 8 | 1212 | 1 | 12 | 6 | ** | 9 | 6 | 3 | 5 |

| 88 | 18 | 2 | 10 | 1212 | 1 | 15 | 8 | ** | 11 | 8 | 4 | 6 |

| 1010 | 21 | 2 | 12 | 1616 | 1 | 18 | 10 | ** | 14 | 10 | 4 | 7 |

| 1212 | 24 | 3 | 15 | 2020 | 1 | 21 | 12 | ** | 16 | 12 | 4 | 7 |

| 1414 | 25 | 3 | 16 | 2020 | 1 | 22 | 14 | ** | 17 | 14 | 5 | 8 |

| 1616 | 27 | 3 | 18 | 2020 | 1 | 24 | 16 | ** | 20 | 16 | 5 | 8 0 |

| 1818 | 31 | 4 | 21 | 2020 | 2 | 27 | 18 | ** | 22 | 18 00 | 6 | 9 |

| 2020 | 33 | 4 | 23 | 2020 | 2 | 29 | 20 | ** | 24 | 20 | 6 | 9 |

| 2424 | 41 | 5 | 27 | 2020 | 2 | 35 | 24 | ** | 29 | 24 0 | 8 | 11 50 |

View Size Chart of Хн65мву (Эп760) Long Weld Neck, UNS N10276 Threaded And Slip On Flange

Nickel Alloy C276 Slip on Flanges Size in MM

| Nickel C276 Flange | 1/2″ (15 NB) to 48″ (1200NB) |

| ASME SB564 Alloy C276 Slip on Flange | 1/2″ NB – 12″ NB |

| ASTM B564 UNS N10276 Blind Flange | 1/2″ NB – 24″ NB |

Hastelloy C276 Forging Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | EN | OR |

| Hastelloy C276 | 2.4819 | N10276 | NW 0276 | – | ХН65МВУ | NiMo16Cr15W | ЭП760 |

Rating of EN - Nimo16cr15w Pipe Flanges

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52000 , MPa – 355 |

| Elongation | 40 % |

Alloy 276 Weld Neck Flange Prices

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

WNR 2.4819 Forged Flange Properties

| Hastelloy C276 Flanges Price List | Alloy C276 Forged Flange Price |

| Hastelloy C276 Flange Prices | US $1.8-159 / Piece |

| Alloy C276 Pipe Flange Price Per kg | US $1500 / Ton |

| Alloy C276 Blind Flange Price | US $1-500 / Piece |

| Price List of ASTM B564 Orifice Flange | US $999-1499 / Piece |

Know Chemical Composition Of NW 0276 Pipe and Socket Weld Flanges

Composition Standard of UNS N10276 Plate Flange

| Ni | Bal |

| Fe | 4-7 |

| Cr | 14.5-16.5 |

| Co | 2.5 max |

| W | 3-4.5 |

| Mo | 15-17 |

| V | 0.35 max |

| C | 0.01 max |

| Mn | 1.0 max |

| P | 0.04 max |

| S | 0.03 max |

| Si | 0.08 max |

Check Hastelloy C276 Flanges Weight Chart Before You Buy ANSI B16.5 Alloy Steel SORF and WNRF Flange

Alloy C276 Flanges Weight

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| AS4087 Flange | PN14 Flange | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flange | 95 | 67 | 4 | 13 | 14 |

| Table D Flange | 95 | 67 | 4 | 13 | 14 | |

| Table E Flange | 95 | 67 | 4 | 13 | 14 | |

| Table F Flange | 95 | 67 | 4 | 13 | 14 | |

| Table H Flange | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Alloy GOST ХН65МВУ Forged Flanges Application

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Off-Shore Oil Drilling Companies

- Power Generation

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry