Suppliers of Cupro Nickel 90/10 Coil and Strip Specification

Check Quenching UNS C70600 Hot Rolled sheet Dimensions, Buy Cuni 90/10 Foils at factory price

90/10 Copper Nickel Plate

Cuni 90/10 Sheet

ASME SB 122 Cu-ni 90/10 Coils

Table of Content

- 90/10 Copper Nickel Plate Specification Chart

- ASTM B122 90/10 Copper Nickel sheet Types

- Cuni 90/10 sheet Weight

- Cupro Nickel 90/10 Foils Dimension Chart

- Thickness Chart of ASME SB 122 Cu-ni 90/10 Coils

- Copper Nickel UNS C70600 Hot Rolled Plates Equivalent Grade

- 90/10 Cu-ni Strips Prices

- Werkstoff No 2.0872 Shim Sheets Properties

- Cuni 90/10 plate Chemical Composition

- ASME SB122 Copper Nickel 90/10 Polished Plates Mechanical Properties

- Cuni DIN 2.0872 Cold Rolled Plates Sizes

- 90/10 Copper Nickel Plate Hs Code

- Processing of 90/10 Copper Nickel Sheet

- UNS C70600 Sheem Sheet Corrosion Resistance

- Uses of Copper Nickel DIN 2.0872 Plate

- Difference Between 90/10 Cuni Plate, Sheet and Foil

- Melting Point of 90/10 Copper Nickel Coil

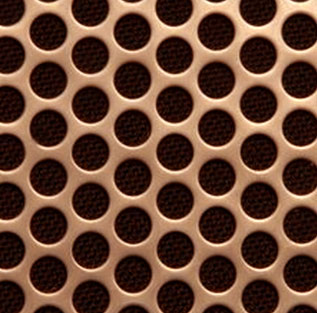

- Cupro Nickel DIN 2.0872 Perforated Sheets Electrical Resistivity

- Thermal Conductivity of 90/10 Copper Nickel Strip

- 90/10 Copper Nickel Plate vs 70/30 Copper Nickel Plate

90/10 Copper Nickel Plate Specification Chart

| End Product | Specification |

|---|---|

| Plate | ASTM B122, MILITARY MIL-C-15726 |

| Plate, Clad | ASTM B432 |

| Plate, Condenser Tube | ASME SB171, ASTM B171, SAE J463, J461 |

| Sheet | ASTM B122, MILITARY MIL-C-15726, SAE J463, J461 |

| Strip | ASTM B122, MILITARY MIL-C-15726 |

| Specifications | ASTM / ASME SB122 |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 0.1mm to 12 mm Thk |

| Form | Sheet, Coil, Plate, Foils, Rolls, Plain Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange), Pata, Patti |

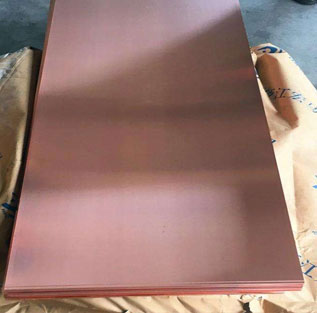

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | Soft, Hard, Quarter Hard, Half Hard, Spring Hard etc. |

| Standard | GB/T5231-2001, GB/T1527-2006, JISH3100-2006, JISH3250-2006, JISH3300-2006, ASTMB152M-06, ASTMB187, ASTMB75M-02, ASTMB42-02, etc. |

| Length Cut to Size | 10mm~12000mm, or as required. |

| Surface | Mill, polished, bright, oiled, hair line, brush, mirror, sand blast, or as required. |

| ASTM | ASME | Military | |

|---|---|---|---|

| Copper Nickel 90/10 Sheet | ASTM B122 | ASME SB-122 | MIL-C-15726 |

| 90/10 Cu-ni Plate | MIL-C-15726 | ||

| 90/10 Cupro Nickel Coil | MIL-C-15726 | ||

| Copper Nickel UNS C70600 Strip | MIL-C-15726 |

ASTM B122 90/10 Copper Nickel sheet Types

Astm C70600 Cuni90/10 Copper Nickel Plate

C70600 Cuni 90/10 Copper Nickel Plate

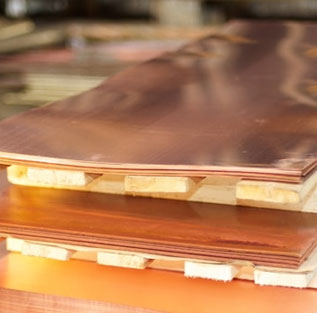

Cuni 90/10 Rolling Sheets

Cuni 90/10 Clad Plate

Cuni 90/10 Nickel Sheet

Copper Nickel Alloy 90 / 10 Sheet Plate / Cupronickel Sheet

Astm B122 Copper Nickel 90/10 Flat Sheet

Uns C70600 Copper Nickel Rolling Plate

Copper Nickel 90/10 Flat Shim

Asme Sb122 Copper Nickel 90/10 Perforated Plate

Cupro Nickel 90/10 Hot Rolled Plate

90/10 Copper Nickel Sheet

ASME SB 122 Cu-ni 90/10 Strip Tape Stockist, Check DIN 2.0872 Cold Rolled Plates & Shim Sheet Weight

Cuni 90/10 sheet Weight

| Thickness | Plate Weight per Unit Area | Density |

|---|---|---|

| 3/16 inches | 0.06000 lbs/in²42.184176 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/4 inches | 0.08 lbs/in²56.245568 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/8 inches | 0.121 lbs/in²85.0714216 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/2 inches | 0.161 lbs/in²113.1942056 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 5/8 inches | 0.196 lbs/in²137.8016416 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/4 inches | 0.235 lbs/in²165.221356 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 7/8 inches | 0.274 lbs/in²192.6410704 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 inches | 0.313 lbs/in²220.0607848 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/4 inches | 0.391 lbs/in²274.9002136 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/2 inches | 0.47 lbs/in²330.442712 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 3/4 inches | 0.549 lbs/in²385.9852104 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 inches | 0.627 lbs/in²440.8246392 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/4 inches | 0.705 lbs/in²495.664068 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/2 inches | 0.784 lbs/in²551.2065664 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 3/4 inches | 0.862 lbs/in²606.0459952 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3 inches | 0.941 lbs/in²661.5884936 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

Cupro Nickel 90/10 Foils Dimension Chart

Cuni 90/10 plate Imperial Dimensions

| Plate Surface finish | Gauge (in) | Width (max in) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed Plate | 10–24 | 72* |

| 2D – Cold rolled, heat treated, pickled plate | 12–24 | 60 |

| BA Mexinox only | 18–28 | 48 |

| Polished plate (not brushed) | 11–24 | 60 |

| Temper rolled plate Mexinox only | 13–29 | 48 |

Cuni DIN 2.0872 Cold Rolled Plate Metric Dimensions

| Plate Surface finish | Thickness (mm) | Width (max mm) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed plate | 0.25–8.0 | 2032 |

| 2D – Cold rolled, heat treated, pickled plate | 0.4–6.35 | 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled plate | 0.4–8.0 | 2032 |

| 2R – Cold rolled, bright annealed plate | 0.25–3.5 | 1524 |

| 2H – Work hardened plate | 0.4–6.35 | 1524 |

| Polished, brushed plate | 0.5–4.0 | 1524 |

Thickness Chart of ASME SB 122 Cu-ni 90/10 Coils

ASTM B122 ASME B171 MILC-15726FAM1/1991 C70600 Sheet

| Thickness In. |

Size In. |

Lbs. Per Sq. Ft. |

Lbs. Per Plate |

|---|---|---|---|

| 1/4 | 48 x 144 | 11.6 | 558 |

| 3/8 | 48 x 144 | 17.4 | 836 |

| 1/2 | 48 x 144 | 23.3 | 1116 |

| 3/4 | 48 x 144 | 34.9 | 1674 |

| 1 | 48 x 144 | 46.5 | 2232 |

| 1 1/4 | 48 x 144 | 58.1 | 2790 |

| Thickness In. |

Size in. |

Lbs. Per Sq. Ft. |

Lbs. Per Plate |

|---|---|---|---|

| 1 1/2 | 48 x 144 | 69.8 | 3348 |

| 2 | 48 x 144 | 93.0 | 4464 |

| 2 1/2 | 48 x 144 | 116.3 | 5582 |

| 3 | 48 x 144 | 139.5 | 6696 |

| 3 1/2 | 48 x 144 | 162.7 | 7914 |

| 4 | 48 x 144 | 186.0 | 8930 |

| 5 | 24 x 96 | 233.0 | 3721 |

ASTM / ASME SB122 90/10 Cupro Nickel Strip Thickness

0.2 mm to 2 mm *

Width: 10 mm to 600 mm *

Copper Nickel UNS C70600 Hot Rolled Plates Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

| Cu-Ni 90/10 | 2.0872 | C70600 |

90/10 Cu-ni Strips Prices

| ASTM B122 UNS C70600 Plate Price | Price in USD (per kg) |

|---|---|

| 90 10 Cu Ni Plate Price | $6 |

| C70600 Shim Plate Price | $9 |

| C70600 Copper Nickel Sheet Price | $12 |

| Copper Nickel 90/10 Sheet | $14 |

Werkstoff No 2.0872 Shim Sheets Properties

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.94 g/cm3 | 0.323 lb/in3 |

Chemical & Mechanical Composition Of Werkstoff No 2.0872 Chequered Plate, Check Best offer on Cuni 90/10 Shim Stock, ASME SB122 Cupro Nickel 90/10 Polished and Perforated Sheet

Cuni 90/10 plate Chemical Composition

| Grade | Cu | Mn | Pb | Fe | Zn | Ni |

| Cupro Nickel 90/10 | 88.6 min | 1.0 max | .05 max | 1.8 max | 1 max | 9-11 max |

ASME SB122 Copper Nickel 90/10 Polished Plates Mechanical Properties

|

State |

Thickness |

Temporary |

Relative |

|---|---|---|---|

|

soft |

less than 0.5 |

not less than 340 |

27 |

|

0.5 and more |

30 |

||

|

semisolid |

less than 0.5 |

440 – 540 |

2 |

|

0.5 and more |

4 |

||

|

solid |

less than 0.5 |

540 – 690 |

– |

|

0.5 and more |

2 |

||

|

extra solid |

less than 0.5 |

more than 690 |

– |

|

0.5 and more |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 303-414 MPa | 43900-60000 psi |

| Tensile strength, yield (depending on temper) | 110-393 MPa | 16000-57000 psi |

| Elongation at break (in 254 mm) | 42.00% | 42.00% |

| Machinability (UNS C36000 (free-cutting brass) = 100%) | 20% | 20% |

| Shear modulus | 52.0 GPa | 7540 ksi |

| Poisson's ratio | 0.34 | 0.34 |

| Elastic modulus | 140 GPa | 20300 ksi |

View 90/10 Copper Nickel Mesh Plate and Perforated Coil Size Chart

Cuni DIN 2.0872 Cold Rolled Plates Sizes

| Size (in inches) | Size (in ) |

|---|---|

| .125 | 3.18 |

| .134 | 3.40 |

| .156 | 3.96 |

| .187 | 4.75 |

| .250 | 6.35 |

| .312 | 7.92 |

| .375 | 9.53 |

| .500 | 12.7 |

| .600 | 15.9 |

| .750 | 19.1 |

| .875 | 22.2 |

| 1 | 25.4 |

| 1.125 | 28.6 |

| 1.250 | 31.8 |

| 1.500 | 38.1 |

| 1.750 | 44.5 |

| 2 | 50.8 |

| 2.500 | 63.5 |

| 3 | 76.2 |

90/10 Copper Nickel Plate Hs Code

| Hs Code | Description |

|---|---|

| 7409 | Copper Plates, Sheets And Strip, Of A Thickness Exceeding 0.15 Mm |

| 74094000 | Of Copper-Nickel Base Alloys (Cupro-Nickel) Or Copper-Nickel-Zinc Base Alloys (Nickel Silver) |

Processing of 90/10 Copper Nickel Sheet

- Hot rolled

- Cold rolled

- Cutting

- Forming Drilling/ Machining

- Grinding

- Polishing

- Testing

UNS C70600 Sheem Sheet Corrosion Resistance

| Iron content % | Semi-fabricated form | Corrosion rate in g/m2at a flow rate in m/s of | |||

|---|---|---|---|---|---|

| 3 | 4.12 | 6.1 | 8.23 | ||

| 0.03 | Bar | 24.7 | 22.9 | ||

| 0.48 | 2.5 | 3.2 | |||

Uses of Copper Nickel DIN 2.0872 Plate

- Gas Processing

- Petrochemical

- Power Generation

- Food Processing

- Chemical

- Oil & Gas

- Fertilizers

- Paper

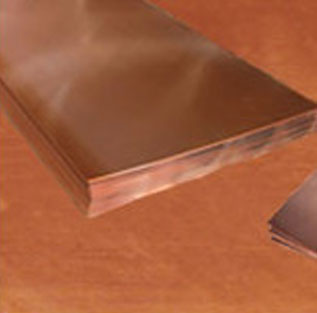

Difference Between 90/10 Cuni Plate, Sheet and Foil

Copper Nickel 90/10 Plate : Thickness greater than 6.35 mm

Copper Nickel 90/10 Sheet : Thickness greater than 0.15 mm and less than 6.35mm .

Copper Nickel 90/10 Foil : Thickness less than 0.15mm.

Melting Point of 90/10 Copper Nickel Coil

| PRODUCT PROPERTY | US CUSTOMARY | METRIC |

| Melting Point - Liquidus | 2100 F | 1149 C |

| Melting Point - Solidus | 2010 F | 1099 C |

Cupro Nickel DIN 2.0872 Perforated Sheets Electrical Resistivity

| PRODUCT PROPERTY | US CUSTOMARY | METRIC |

| Electrical Conductivity | 9 %IACS @ 68 F | 0.053 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 115.0 ohms-cmil/ft @ 68 F | 19.12 microhm-cm @ 20 C |

| Specific Heat Capacity | 0.09 Btu/lb/oF at 68 F | 377.1 J/kg . oK at 293 K |

Thermal Conductivity of 90/10 Copper Nickel Strip

| PRODUCT PROPERTY | US CUSTOMARY | METRIC |

| Coefficient of Thermal Expansion | 9.5 . 10-6 per oF (68-572 F) | 17.1 . 10-6 per oC (20-300 C) |

| Thermal Conductivity | 26.0 Btu . ft/(hr . ft2 . oF)at 68F | 45.0 W/m . oK at 20 C |

90/10 Copper Nickel Plate vs 70/30 Copper Nickel Plate

90/10 has high strength corrosion resistance with high toughness and ductility, used in marine, architectural and industrial applications. Whereas, 70/30 copper nickel alloys have great resistance to sea water-related corrosion due to the presence of significant amounts of iron and manganese. Check chemical Composition Chart

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Copper Nickel 90/10 Plate | 88.6 min | 1.0 max | .05 max | 9-11 max | 1.8 max | 1 max |

| Copper Nickel 70/30 Plate | 65 min | 1.0 max | 0.05 max | 29-33 max | 0.4-1.0 max | 1 max |