ASTM B702 WCu 80/20 Rod and Square Bar Suppliers

Stockist of Copper Tungsten 70/30 Threaded Rod, Check Specification of Alloy R07100 Hex and Flat Bar Standards

Tungsten Round Bar

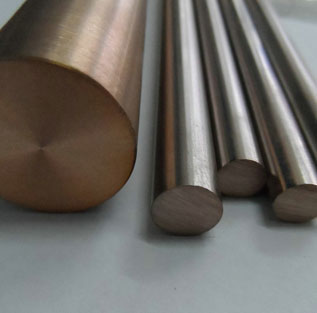

Copper Tungsten 70/30 Rod

WCu 80/20 Hex Bar

Table of Content

- Specification of Tungsten Round Bar

- Copper Tungsten Rod Types

- Difference Between Tungsten Round bar and Titanium Round Bar

- Copper Tungsten 70/30 Rod Tolerance

- Price of Tungsten Rod

- Weight of ASTM B702 WCu 80/20 Hex Bar

- Copper Tungsten 90/10 Bright Bars machining

- WCu 70/30 Flat Bar physcial Composition li>Mechanical Properties of Tungsten Copper Alloy R07030 Forged Bar

- Size Chart of Alloy R07100 Tungsten Hollow Bar

Specification of Tungsten Round Bar

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 2~15 | <500 | <500 |

| 1~2 | <500 | <1000 |

| 0.5~1 | <500 | <500 |

| 0.3~0.5 | <500 | <500 |

| 0.2~0.3 | <500 | <500 |

Copper Tungsten Rod Types

99.95% Pure Tungsten Round Rod, Diameter: 1.000 (1 inch), Length: 6 inches

Tungsten Copper Rod - 0.25'' Diameter x 12'' Length

99.95% pure tungsten rounds rods/bars

99.95% Pure Tungsten Rod, W Rod, Tungsten Bar

4mm Copper Tungsten Bar

WT20 2.4mm*150mm Tungsten Bar

Length 330mm Tungsten Carbide Solid Round Bar

pure 2.4mm 5mm large copper alloy rod

4.8-6.4mm ASTM B777 copper rod with w80/cu20

20mm ASTM B777 Bright Bars

Difference Between Tungsten Round bar and Titanium Round Bar

Tungsten Round bar

Tugsten Bar is pure metal, it has good thermal conductivity, good electrical conductivity. Tungsten, sometimes called “wolfram” and identified as W. It is used in nuclear, automotive and aerospace sectors. Check pure Tungsten Composition

| Al | Ca | Fe | Mg | Ni | Si | C | N | O | Mo | W1 |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.002 | 0.005 | 0.005 | 0.003 | 0.003 | 0.005 | 0.008 | 0.003 | 0.005 | 0.01 | >=99.95% |

Titanium Round Bar

titanium bars are durable and combine high strength with low weight. Check Below Chemical Composition

| Grade | C | N | O | H | Ti | V | Al | Fe |

| Gr 1 | .08 Max | .03 Max | .18 Max | .015 Max | Bal | .20 Max | ||

| Gr 2 | 0.10 max | 0.03 max | 0.25 max | 0.015 max | bal | 0.30 max | ||

| Gr 4 | .08 Max | .05 Max | .40 Max | .015 Max | Bal | .50 Max | ||

| Gr 5 | 0.10 max | 0.05 max | 0.20 max | 0.015 max | bal | 3.5-4.5 | 5.5-6.75 max | 0.40 max |

| Gr 7 | .08 Max | .03 Max | .25 Max | .015 Max | Bal | .30 Max | ||

| Gr 9 | .08 Max | .03 Max | .15 Max | .015 Max | - | .25 Max | ||

| Gr 12 | .08 Max | .03 Max | .25 Max | 0.15 Max | - | .30 Max |

Copper Tungsten 70/30 Rod Tolerance

| Tolerances for Tungsten Round Bar | ||

|---|---|---|

| Shape / Section | Size, diameter or width across flats | Permitted variation |

| milimeter | milimeter | |

| Round | ≥6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 100 |

+ 0 to - 0.070 + 0 to - 0.085 + 0 to - 0.100 + 0 to - 0.120 + 0 to - 0.140 |

| Flat (thickness) | < 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 |

+ 0 to - 0.110 + 0 to - 0.130 + 0 to - 0.250 + 0 to - 0.350 |

| Flat (width) | < 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 100 > 100 ≦ 130 > 130 ≦ 160 > 160 ≦ 320 |

+ 0 to - 0.110 + 0 to - 0.130 + 0 to - 0.160 + 0 to - 0.190 + 0 to - 0.220 + 0 to - 0.350 + 0 to - 1.00 + 1.00 to - 1.00 |

| Square and hexagon |

≥ 6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 105 |

+ 0 to - 0.090 + 0 to - 0.110 + 0 to - 0.130 + 0 to - 0.160 + 0 to - 0.250 |

Tolerances of Turned ASTM B777 Flat Bar (BS 970-3)

| Turned ASTM B777 Flat Bar Tolerances | |

|---|---|

| Tungsten Copper Rod diameter and sizes | Permitted variation |

| milimeter | milimeter |

| ≧ 6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 120 > 120 ≦ 180 > 180 ≦ 250 > 250 ≦ 315 > 315 ≦ 400 > 400 |

+ 0 to - 0.070 + 0 to - 0.085 + 0 to - 0.100 + 0 to - 0.120 + 0 to - 0.140 + 0 to - 0.160 + 0 to - 0.185 + 0 to - 0.210 + 0 to - 0.230 + 0 to - 0.250 |

Tolerances of Precision UNS R07004 Copper Rod (BS 970-3)

| Precision ASTM B777 Tungsten Bright Bars Tolerances | ||||

|---|---|---|---|---|

| Section | Size, diameter |

Permitted overall variation | ||

| Class A | Class B | Class C | ||

| mm | mm | mm | mm | |

| Round | ≧ 6 <75 | 0.05 | 0.025 | 0.013 |

Tolerance of cold rolled Tungsten Hollow Bar (BS EN ISO 286-2 )

| Cold Drawn Tungsten Square Bar Tolerance ISO “H” Series in MM | ||||||||

|---|---|---|---|---|---|---|---|---|

| NOMINAL SIZE Chart | h5 | h6 | h7 | h8 | h9 | H10 | H11 | h12 |

| DIAMETER milimete | ||||||||

| ~ to 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| 3 to 6 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| 6 to 10 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| 10 to 18 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| 18 30 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| 30 to 50 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| 50 to 80 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| 80 to 120 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| 120 to 180 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| 180 to 250 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |

AcceView Dimension of UNS R07030 Forged and Hollow Bar & Check Tungsten Rod Price

Price of Tungsten Rod

| Tungsten Copper Rod Price List | Price |

|---|---|

| UNS R07100 Round Bar Price | $5.00-$50.00/ Piece |

| ASTM B777 Flat Bar Prices | $38.80-$39.80/ Kilogram |

| cold rolled Tungsten Hollow Bar Price Per Kg | $64.00-$78.00/ Piece |

| Tungsten Square Bar Price | $55.15-$57.97/ Kilogram |

Weight of ASTM B702 WCu 80/20 Hex Bar

| Round Bar | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size in milimeter | Kgs / Foot | Kgs / Mtr | Size in milimeter | Kgs / Foot | Kgs / Mtr | Size in inch | Kgs / Foot | Kgs / Mtr |

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3 | 0.017 | 0.055 | 20 | 0.753 | 2.470 | 3" | 10.900 | 35.762 |

| 1/8" | 0.019 | 0.062 | 22 | 0.908 | 2.979 | 3-1/4" | 12.800 | 41.996 |

| 5/32" | 0.029 | 0.095 | 7/8" | 0.926 | 3.038 | 3-1/2" | 14.850 | 48.772 |

| 4 | 0.030 | 0.098 | 24 | 1.080 | 3.543 | 3-3/4" | 17.001 | 55.780 |

| 3/16" | 0.043 | 0.141 | 25 | 1.180 | 3.871 | 4" | 19.306 | 63.340 |

| 5 | 0.047 | 0.154 | 1" | 1.210 | 3.970 | 4-1/4" | 21.908 | 72.249 |

| 7/32" | 0.058 | 0.190 | 26 | 1.271 | 4.170 | 4-1/2" | 24.4487 | 80.340 |

| 6 | 0.068 | 0.223 | 27 | 1.368 | 4.490 | 4-3/4" | 27.366 | 90.249 |

| 1/4" | 0.076 | 0.249 | 1-1/8" | 1.534 | 5.033 | 5" | 30.461 | 99.940 |

| 7 | 0.091 | 0.298 | 30 | 1.691 | 5.548 | 5-1/2" | 36.690 | 121.000 |

| 5/16" | 0.118 | 0.387 | 1-1/4" | 1.924 | 6.349 | 6" | 43.860 | 143.900 |

| 8 | 0.120 | 0.398 | 32 | 1.894 | 6.314 | 6-1/2" | 51.093 | 167.630 |

| 9 | 0.152 | 0.498 | 1-3/8" | 2.303 | 7.550 | 7" | 59.432 | 196.000 |

| 3/8" | 0.170 | 0.557 | 35 | 2.390 | 7.553 | 7-1/2" | 68.226 | 225.000 |

| 10 | 0.189 | 0.620 | 36 | 2.438 | 7.999 | 8" | 77.586 | 254.55 |

| 11 | 0.228 | 0.748 | 38 | 2.792 | 8.903 | 10" | 121.048 | 397.140 |

| 7/16" | 0.232 | 0.761 | 1-1/2" | 2.715 | 8.951 | |||

| 12 | 0.271 | 0.889 | 40 | 3.009 | 9.872 | |||

| 1/2" | 0.303 | 0.994 | 1-5/8" | 3.200 | 10.449 | |||

| 13 | 0.318 | 1.043 | 1-3/4" | 3.712 | 12.179 | |||

| 14 | 0.368 | 1.207 | 45 | 3.807 | 12.555 | |||

| 9/16" | 0.383 | 1.256 | 1-7/8" | 4.260 | 13.977 | |||

| 15 | 0.424 | 1.391 | 48 | 4.330 | 14.205 | |||

| 5/8" | 0.473 | 1.551 | 50 | 4.698 | 15.414 | |||

| 16 | 0.481 | 1.578 | 2" | 4.848 | 15.906 | |||

| 17 | 0.543 | 1.791 | 2-1/8" | 5.475 | 17.963 | |||

| 11/16" | 0.573 | 1.880 | 2-1/4" | 6.135 | 20.128 | |||

| 18 | 0.610 | 2.001 | 60 | 6.768 | 22.205 | |||

| 3/4" | 0.682 | 2.237 | 2-3/8" | 6.838 | 22.435 | |||

| 2-1/2" | 7.576 | 24.856 | ||||||

| 2-5/8" | 8.354 | 27.409 | ||||||

| 2-3/4" | 9.169 | 30.083 | ||||||

Copper Tungsten 90/10 Bright Bars machining

- Turning

- Milling

- Drilling

- Cutting

- Grinding

- Stamping

- Joining

- Forming

- EDM Machining

WCu 70/30 Flat Bar physcial Composition

| Composition | Density | Electrical Conductivity | CTE | Thermal Conductivity | Hardness | Tensile Strength |

| g/cm³ | IACS % Min. | 10-6 K-1 | W/m · K-1 | HRB Min. |

Mpa Min. | |

| WCu 50/50 | 11.70 | 56 | 13 | - | 69 | 344 |

| WCu 55/45 | 12.50 | 55 | 12 | - | 79 | 360 |

| WCu 60/40 | 12.75 | 49 | 11.8 | - | 85 | 380 |

| WCu 70/30 | 13.80 | 44 | 10.3 | 200 | 90 | 516 |

| WCu 75/25 | 14.50 | 48 | 10.22 | 190 | 95 | 585 |

| WCu 80/20 | 15.15 | 40 | 9.20 | 180 | 100 | 620 |

| WCu 90/10 | 16.75 | 27 | 7.4 | 170 | - | 700 |

Check Properties of Tungsten Carbide Round Bar, Copper Tungsten 90/10 Bright Bars Importers

Mechanical Properties of Tungsten Copper Alloy R07030 Forged Bar

| Diameter | 0.029″ (0.75mm) – 5″ (127 mm) |

| Length | 0.15″ (3.81mm) – 40″ (1000mm) |

| Types | WCu10, WCu20, WCu25, WCu30, WCu40, WCu45, WCu50 |

| Standard | ASTM B702 |

| Material | R07030, R07004, R07100 |

| Standard | ASTM B777, ASME SB777 |

| Size | 5.0 milimeter diameter x L |

| Surface | Turning, Grinding |

We Maintain Copper Tungsten 90/10 Polished Bar Stock Good Quality, Check available sizes of R07030 Threaded Rod

Size Chart of Alloy R07100 Tungsten Hollow Bar

| Type | SIZES in milimeter | SIZES in inches | Tolerance |

|---|---|---|---|

| Peeled and Polished | 40.00 - 150.00 | 1.50 - 6.00 | h11, h11-DIN 1013 |

| Cold Drawn and Polish | 3.00 to 75.00 | 1/8 to3.00 | h8 to h11 |

| Cold Drawn and Ground | 10.00 to 75.00 | 5/6 to 2.50 | h8 to h11 |

| Peeled nd Ground | 20.00 - 50.00 | 3/4 - 2.00 | h9 to h11 |

Tungsten Round Bars Standard lengths of 2000 mm up to 6000 mm.

| 5.0 | 45.0 |

| 6.0 | 50.0 |

| 7.0 | 55.0 |

| 8.0 | 60.0 |

| 9.0 | 65.0 |

| 10.0 | 70.0 |

| 12.0 | 75.0 |

| 16.0 | 80.0 |

| 20.0 | 90.0 |

| 25.0 | 100.0 |

| 30.0 | 130.0 |

| 35.0 | 160.0 |

| 40.0 | 200.0 |

Stocking Distributor Of tungsten Round Bar Following Manufacturers in UAE

Stockist of Copper Tungsten 70/30 Rod in UAE