Alloy 600 Pipe Fittings Stockist, Check ASTM B366 Inconel Fitting Weight Chart in MM

Check Inconel Pipe Fittings Dimensions in MM, Looking to Buy ASTM B366 UNS N06600 Buttweld Tee from Supplier

Inconel Fittings

ASTM B366 UNS N06600 Buttweld Tee

Inconel 600 Elbow

Inconel Pipe Fittings

Inconel 600 Pipe Fittings

ASME SB 366 Inconel 600 Buttweld Fittings

Table of Content

- Inconel 600 Pipe Fittings Specification Chart

- Various Types of ASTM B366 Inconel Fittings

- Rating of Inconel Pipe Fittings

- ASTM B366 UNS N06600 Buttweld Tee Weight

- Dimension of Alloy Inconel 600 Fittings

- SB366 Inconel 600 Buttweld Fittings Standards

- Composition Standard of 600 Inconel Buttweld Elbow

- 2.4816 inconel pipe fittings Equivalent

- Characteristics of Alloy 600 Seamless Pipe Fittings

- ASME SB 366 UNS N06600 Pipe Elbow Properties

- 600 Alloy Cross Prices

- Mechanical Properties of JIS NCF 600 Reducer

- EN NiCr15Fe End Cap Application

Alloy Inconel 600 Fittings Stock, Largest Importers of SB366 DIN 2.4816 Buttweld Fitting, 600 Inconel Buttweld Elbow Specification

Inconel 600 Pipe Fittings Specification Chart

| Grade | Inconel Alloy 600 / UNS N06600 |

| Standard | ASTM B366, ASME SB366 |

| Dimensions | ASME B16.28, ASME/ANSI B16.9, MSS-SP-43 |

| Inconel 600 Seamless Fittings | 1/2" NB - 10" NB |

| Inconel 600 Welded Fittings | 1/2" NB - 48" NB |

| Form | 90 Elbow, 45 Elbow, Long Radius Elbow, Short Radius Elbow, Concentric Reducer, Eccentric Reducer, Equal Tee, Unequal Tee, Lateral Tee, Cross, Bends 1.5d, 3d, 5d, 10d, U bend, 180 Deg Bend, Short Stub End, Long stub end, End Cap, Dish Cap |

| Schedule | SCH 5 To SCH XXS |

| Wall Thickness | from 2 to 40 mm |

| Type | Seamless / Welded / Fabricated |

Various Types of ASTM B366 Inconel Fittings

Steel Pipe Fitting 8" Sch 40 Elbow Inconel 600 Asme/ansi B16.9

ASTM B366 Inconel 600 Butt-welding Fittings

Inconel 600 Elbow Tee Pipe Fitting 30 Degree Pipe Elbow

ASTM B366 Inconel 600 Bw Seamless Pipe Fittings

ASTM B366 Inconel Alloy 600 Buttweld Fittings

Inconel 600 Alloy Pipe Fittings

ASTM Sus Inconel 600 Nickel Alloy Pipe Concentric Reducer

Inconel 600 Bw Pipe Fitting Elbow Reducer Tee Stud Ends

Rating of Inconel Pipe Fittings

| Pipe Size (inches) |

Pipe Schedule | Outside Diameter (in) |

Wall Thickness (in) |

Temperature (oF) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||||

| Allowable Stress (psi) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

ASTM B366 UNS N06600 Buttweld Tee Weight

Inconel 600 Reducing Tee Weight in Kg, Equal Tee Weight, Straight Tee Weight Chart

| Sch STD | Sch XS | |||

| NPS | LBS | KG | LBS | KG |

| 1/2 | 0.35 | 0.16 | 0.45 | 0.2 |

| 3/4 | 0.45 | 0.2 | 0.6 | 0.27 |

| 1 | 0.75 | 0.34 | 0.88 | 0.4 |

| 1.1/4 | 1.3 | 0.59 | 1.6 | 0.73 |

| 1.1/2 | 2 | 0.91 | 2.25 | 1.02 |

| 2 | 3.5 | 1.59 | 4 | 1.81 |

| 2.1/2 | 6 | 2.72 | 7 | 3.18 |

| 3 | 7 | 3.18 | 8.5 | 3.86 |

| 3.1/2 | 9 | 4.08 | 12 | 5.44 |

| 4 | 12 | 5.44 | 15.8 | 7.17 |

| 5 | 21 | 9.53 | 26 | 11.79 |

| 6 | 34 | 15.42 | 40 | 18.14 |

| 8 | 55 | 24.95 | 75 | 34.02 |

| 10 | 85 | 38.56 | 105 | 47.63 |

| 12 | 120 | 54.43 | 160 | 72.57 |

| 14 | 165 | 74.84 | 240 | 108.86 |

| 16 | 195 | 88.45 | 280 | 127.01 |

| 18 | 249 | 112.94 | 332 | 150.59 |

| 20 | 342 | 155.13 | 480 | 217.72 |

| 22 | 414 | 187.79 | 550 | 249.48 |

| 24 | 528 | 239.5 | 610 | 276.69 |

| 26 | 770 | 349.27 | 875 | 396.89 |

| 30 | 1060 | 480.81 | 1200 | 544.31 |

| 36 | 1490 | 675.85 | 1700 | 771.11 |

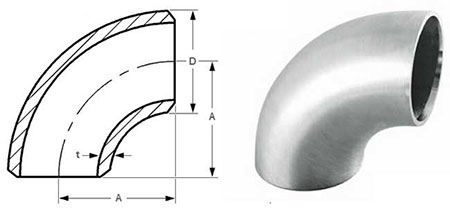

Dimension of Alloy Inconel 600 Fittings

| NPS | O.D. D |

90deg Long Radius Center to End A |

90deg 3D Center to End A |

| 1/2 | 21.3 | 38 | ... |

| 3/4 | 26.7 | 38 | 57 |

| 1 | 33.4 | 38 | 76 |

| 1.1/4 | 42.2 | 48 | 95 |

| 1.1/2 | 48.3 | 57 | 114 |

| 2 | 60.3 | 76 | 152 |

| 2.1/2 | 73 | 95 | 190 |

| 3 | 88.9 | 114 | 229 |

| 3.1/2 | 101.6 | 133 | 267 |

| 4 | 114.3 | 152 | 305 |

| 5 | 141.3 | 190 | 381 |

| 6 | 168.3 | 229 | 457 |

| 8 | 219.1 | 305 | 610 |

| 10 | 273 | 381 | 762 |

| 12 | 323.8 | 457 | 914 |

| 14 | 355.6 | 533 | 1067 |

| 16 | 406.4 | 610 | 1219 |

| 18 | 457 | 686 | 1372 |

| 20 | 508 | 762 | 1524 |

| 22 | 559 | 838 | 1676 |

| 24 | 610 | 914 | 1829 |

| 26 | 660 | 991 | 1981 |

| 28 | 711 | 1067 | 2134 |

| 30 | 762 | 1143 | 2286 |

| 32 | 813 | 1219 | 2438 |

| 34 | 864 | 1295 | 2591 |

| 36 | 914 | 1372 | 2743 |

| 38 | 965 | 1448 | 2896 |

| 40 | 1016 | 1524 | 3048 |

| 42 | 1067 | 1600 | 3200 |

| 44 | 1118 | 1676 | 3353 |

| 46 | 1168 | 1753 | 3505 |

| 48 | 1219 | 1829 | 3658 |

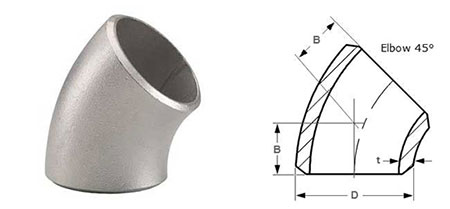

| NPS | O.D. D |

45deg Long Rad Center to End B |

45deg 3D Center to End B |

||

| 1/2 | 21.3 | 16 | ... | ||

| 3/4 | 26.7 | 19 | 24 | ||

| 1 | 33.4 | 22 | 31 | ||

| 1.1/4 | 42.2 | 25 | 39 | ||

| 1.1/2 | 48.3 | 29 | 47 | ||

| 2 | 60.3 | 35 | 63 | ||

| 2.1/2 | 73 | 44 | 79 | ||

| 3 | 88.9 | 51 | 95 | ||

| 3.1/2 | 101.6 | 57 | 111 | ||

| 4 | 114.3 | 64 | 127 | ||

| 5 | 141.3 | 79 | 157 | ||

| 6 | 168.3 | 95 | 189 | ||

| 8 | 219.1 | 127 | 252 | ||

| 10 | 273 | 159 | 316 | ||

| 12 | 323.8 | 190 | 378 | ||

| 14 | 355.6 | 222 | 441 | ||

| 16 | 406.4 | 254 | 505 | ||

| 18 | 457 | 286 | 568 | ||

| 20 | 508 | 318 | 632 | ||

| 22 | 559 | 343 | 694 | ||

| 24 | 610 | 381 | 757 | ||

| 26 | 660 | 406 | 821 | ||

| 28 | 711 | 438 | 883 | ||

| 30 | 762 | 470 | 964 | ||

| 32 | 813 | 502 | 1010 | ||

| 34 | 864 | 533 | 1073 | ||

| 36 | 914 | 565 | 1135 | ||

| 38 | 965 | 600 | 1200 | ||

| 40 | 1016 | 632 | 1264 | ||

| 42 | 1067 | 660 | 1326 | ||

| 44 | 1118 | 695 | 1389 | ||

| 46 | 1168 | 727 | 1453 | ||

| 48 | 1219 | 759 | 1516 | ||

SB366 Inconel 600 Buttweld Fittings Standards

| UNS: | N06600 |

| Specifications: | ASTM B366 |

| international Specifications: | BS 3072-3076 (NA14) DIN 17742, DIN 17750, DIN 17754 WERKSTOFF Nr 2.4816 TÜV 305 AFNOR-NC 15 Fe |

Composition Standard of 600 Inconel Buttweld Elbow

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

2.4816 inconel pipe fittings Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Characteristics of Alloy 600 Seamless Pipe Fittings

- Corrosion resistance

- Resistance to oxidation and sulfidation

- Cryogenic strength

- Resistance to abrasion and erosion

- Surface finish

- Magnetic properties

- Ductility

- Elevated temperature strength

- Stability of properties in service

- Suitability for intended fabrication techniques

ASME SB 366 UNS N06600 Pipe Elbow Properties

| Density | lb/in³ | 0.305 |

|---|---|---|

| Mg/m³ | 8.44 | |

| Specific Heat | Btu/lb°F (J/kg°C) | 0.106 |

| J/kg-°C | 444 | |

| Melting Range | °F | 2470-2575 |

| °C | 1354-1413 | |

| Electrical Resistivity | ohm-circ mil/ft | 620 |

| μΩ-m | 1.03 | |

| Curie Temperature | °F | -192 |

| °C | -124 | |

| Permeability | 200 oersted (15.9 kA/m) | 1.01 |

Purchase GOST МНЖМц 28-2,5-1,5 inconel seamless pipe fittings at best Price, Ask For ready stock of ASME SB 366 EN NiCr15Fe Pipe Elbow

600 Alloy Cross Prices

| Inconel 600 UNS N06600 Pipe Fittings | ASTM B366 600 Inconel Alloy Weld Fittings Price in USD |

| Inconel 600 1/2″ Tee | $1407.2 |

| Inconel 600 UNS N06601 90 Deg LR Seamless Elbow | $1296.2 |

| Cost of Alloy 601 Class 3000 1/8″ Elbow | $710.7 |

Mechanical Properties of 600 Alloy Cross, Check JIS NCF 600 Reducer, BS NA 13 End Cap Size Chart

Mechanical Properties of JIS NCF 600 Reducer

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

EN NiCr15Fe End Cap Application

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry