Supplier of AWS A5.9 SS ER316LSi Welding Rod

PED Approved UNS S31683 Mig Rod and Filler Wire Stockist

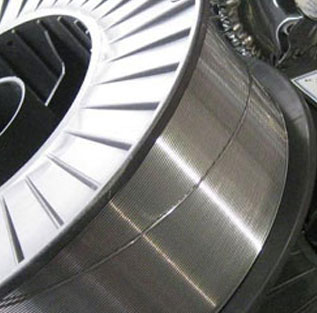

Stainless Steel ER 316L Filler Wire

Stainless Steel ER-316LSi Welding Wire

AWS A5.9 SS ER316LSi Welding Rod

Table of Content

- Stainless Steel ER 316L Filler Wire Specification List

- Common Types of AWS A5.9 SS ER316LSi Welding Rod

- Size Chart of Stainless Steel ER-316LSi Welding Wire

- UNS S31683 Mig Rod Chemical Analysis

- Mechanical Composition of ER 316L Stainless Steel Welding Electrode

- Stainless Steel ER316LSi Tig Rod GMA Welding Parameter

- Stainless Steel ER 316L Filler Rod Equivalent grade

- Price List of DIN 1.4430 Welding Rod

Stainless Steel ER 316L Filler Wire Specification List

| Specification | AWS A5.9 ER-316L, ER-316LSi, A5.9M:2006 |

| Soft Wire Diameter Range in Milimeter | 0.06 – 2.30 milimeter |

| Hard Wire Diameter Range in milimeter | 0.30 – 3.00milimeter |

| Diameter Chart | .035â€, .045â€, 1/16â€, 3/32â€, 1/8â€, 5/32†|

| Customized Length | 36 Inch (914milimeter) |

| Materials | ER-316LSi Stainless Steel |

| Wire Forms | Wires, Filler Wires, Coil Wires, Welding Wires |

Common Types of AWS A5.9 SS ER316LSi Welding Rod

Stainless Steel Welding Wire Price Welding Rod Submerged Wire 316L

Aws 5.9 Tig ER 316L Stainless Steel Welding Wire

316L Stainless Steel Tig Welding Wire

ER316L SS Flux Cored Welding Wire

Aws A5.9 ER316L Tig Stainless Steel Welding Solid Wire 316L Rod 4mm 1mm

Stainless Steel Welding Rods 316 And Mig 316L Stainless Steel Welding Wire 0.035 0.045 Inch

ER316Lsi Stainless Steel Flux Cored Welding Wire Flux Cored Wire

ER316L Stainless Steel Mig And Tig Welding Wire

Stainless Steel Tig Wire ER 316L Filler Wire

316L Filler Rod

Weight Chart & Sizes Of ER 316L Stainless Steel Welding Electrode, Accept all small/ Large Orders UNS S31688 Tig Rod

Size Chart of Stainless Steel ER-316LSi Welding Wire

| Diameter X Spool Sizes Chart | Diameter X Coil Sizes Chart |

| .035 x 2#, 10#, 25#, 30#, 33# | 3/32 x 60# & mill coil |

| .045 x 2#, 10#, 25#, 30#, 33# | 1/8 x 60# & mill coil |

| .025 x 2#, 10#, 25# | 1/16 x 60# & mill coil |

| .030 x 2#, 10#, 25#, 30#, 33# | 5/64 x 60# & mill coil |

| 1/16 x 10#, 25#, 30#, 33# | 3/16 x 60# & mill coil |

| 5/32 x 60# & mill coil |

UNS S31683 Mig Rod Chemical Analysis

| Chemical Composition Limits | |||||||||

| Weight% | C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

| ER 316 ER 316L |

0.04-0.08 | 1.0-2.5 | 0.30-0.65 | 18-20 | 11-14 | 0.03 max | 0.03 max | 2-3 | 0.75 max |

| SS ER-316LSi | 0.02 | 1.70 | 0.85 | 19.0 | 12.5 | - | 0.025 | - | 0.40 |

Check Also EN 19 12 3 L Filler Rod Mechanical properties, View Pressure Rating of DIN 1.4430 MIG Welding Rod

Mechanical Composition of ER 316L Stainless Steel Welding Electrode

| Material | Ultimate Tensile Strength | Offset Yield Strength 0.2 % | Elongation (%) | ||

| psi | MPa | psi | MPa | ||

| ER 316 / ER 316L | 84,100 | 580 | 58,000 | 400 | 38 |

| SS ER-316LSi | 87,000 | 600 | 57,000 | 393 | 38 |

Stainless Steel ER316LSi Tig Rod GMA Welding Parameter

| Recommended Welding Parameters | ||||||

| GMAW “Mig Process” | Reversed Polarity | |||||

| Wire Diameter | Wire Feed | Amps | Volts | Shielding Gas | Gas CFH | |

| Short Arc Welding | .030 | 13-26 | 40-120 | 16-20 | Argon+2% O2 | 25 |

| .035 | 13-26 | 60-140 | 16-22 | Argon+2% O2 | 25 | |

| Spray Arc Welding | .035 | 20-39 | 140-220 | 24-29 | Argon+2% O2 | 38 |

| .045 | 16-30 | 160-260 | 25-30 | Argon+2% O2 | 38 | |

| 1/16 | 10-16 | 230-350 | 27-31 | Argon+2% O2 | 38 | |

Other shielding Gases may be used for Mig welding. Shielding gases are chosen taking Quality, Cost, and Operability into consideration

| Recommended Welding Parameters | ||

| SAW “Submerged Arc Welding Process” | Reversed Polarity Suggested | |

| Wire Diameter | Amps | Volts |

| 3/32 | 250-450 | 28-32 |

| 1/8 | 300-500 | 29-34 |

| 5/32 | 400-600 | 30-35 |

| 3/16 | 500-700 | 30-35 |

Stainless Steel ER 316L Filler Rod Equivalent grade

| STANDARD | AWS | UNS | DIN | Class | EN | BS |

|---|---|---|---|---|---|---|

| SS ER-316L | A5.9 | S31683 | 1.4430 | ER316L | 19 12 3 L | 316S92 |

| SS ER-316LSi | A5.9 | S31688 | 1.4430 | ER316LSi | 19 12 3 LSi | 316S93 |

Application of UNS S31683 Mig Welding Wire

- ASTM A743, A744 Types CF-8 and CF-3

- Developed for welding type 316 and 316L stainless steels

- For joining the more common austenitic stainless steel grades referred to as “18-8” steels

- For very good corrosion resistance in acid environments

- Power Generation

- Chemical and Petrochemical Processing

Importers of BS 316S92 Tig and Mig Welding Wire. Buy Class ER316LSi Flux Cored Arc Welding Wire at best Price

Price List of DIN 1.4430 Welding Rod

| Stainless Steel ER 316L Filler Wire Price List | Stainless Steel ER-316LSi Filler Wire Prices |

| stainless steel 316L welding filler rod/tig welding filler rods, | US $1000-$5400 / Ton |

| stainless mig wire er 316l filler wire | US $3.20-$5.60 / Kilogram |

| Stainless Steel MIG Welding Wire rod ER316 ER316L ER316LSi | US $3000-$3200 / Ton |

| ER 316LSi stainless steel tig weld wire 1mm 1.2mm 0.8mm 1.5mm | US $1000-$6500 / Ton |

Stock Of Stainless Steel ER 316L Filler Wire Following Manufacturers in UAE

AWS A5.9 SS ER316LSi Welding Rod Stockist in UAE

Stockholder Of Stainless Steel ER-316LSi Welding Wire in UAE

UNS S31683 Mig Rod Stockholder in UAE

Supplier Of ER 316L Stainless Steel Welding Electrode in UAE

Stainless Steel ER316LSi Tig Rod Supplier in UAE

Stock Of Stainless Steel ER 316L Filler Rod in UAE

DIN 1.4430 Welding Rod Stock in Dubai

Stainless Steel ER316L Tig Wire Stocking Distributor in Dubai

Stocking Distributor Of UNS S31683 Mig Welding Wire in Dubai