Nickel Alloy 600 Nut And Stud Bolts Suppliers

PED Certified UNS N06600 Threaded Stockist, Check Inconel Fasteners Specification

Inconel Fasteners

Inconel 600 Fasteners

Nickel Alloy 600 Hex Bolts

Inconel 600 Nuts

Inconel 600 Screws

Inconel Nuts and Bolts

Table of Content

- ASME B18.2.1 Inconel Fasteners Specification Chart

- Inconel Bolts Types

- Alloy Inconel 600 Fasteners Chemical Composition

- Inconel Nuts and Bolts Mechanical Properties

- Nickel Alloy 600 Hex Bolts Equivalent Grade

- ASTM B166 Inconel 600 Bolts Physical Properties

- Inconel 600 Nuts Prices

- Alloy 600 Stud Bolts Dimension Chart

- Grade N06600 Bolts and Nuts Weight

- SB166 Inconel 600 Screws Grade Chart

- WERKSTOFF NR. 2.4816 Threaded Rod Uses

- Properties of 600 Alloy Socket Head Cap Screws

- Inconel Fasteners VS Monel Fasteners

- Alloy 600 Fasteners Sizes

ASME B18.2.1 Inconel Fasteners Specification Chart

| ASTM Specification | ASTM B166 / ASME SB166 |

| Standard | DIN, ASTM, BS and all International Standards |

| Size | 3 mm to 200 mm |

| Bolt / Screw Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Washers Size | M1 - M64 | #4 to 3" | Custom Sizes |

| Length | M02 to M33 |

Inconel Bolts Types

Inconel 600 Fasteners Uns N06600

Inconel 600 Nut And Bolt

Inconel 600 Socket Cap Screws

Inconel 600 Thread Rod Stud Bolt Nuts Washers Fasteners

Inconel 600 Socket Cap Screw

Inconel 600 Nut / Bolt / Washer / Fasteners

Inconel 600 Nickel Alloy Nut Bolt

Alloy Inconel 600 Stud Bolt

Uns N06600 Alloy Inconel 600 Bolts

Inconel 600 2.4816 N06600 Din933 Hex Bolt

Alloy Inconel 600 Fasteners Chemical Composition

| Grade | C | Mn | Si | Fe | S | Cr | Cu | Ni | |

| 600 | min. | – | – | – | 6.0 | – | 14.0 | – | 72.0 |

| max. | 0.15 | 1.0 | 0.5 | 10.0 | 0.015 | 17.0 | 0.5 | – | |

Inconel Nuts and Bolts Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 600 | Psi – 95,000 , MPa -655 | Psi – 45,000 , MPa – 310 | 40 | – | – |

Equivalent Of DIN 2.4816 Hex Bolts, Get Free Quote For ASME SB166 JIS NCF 600 Washer

Nickel Alloy 600 Hex Bolts Equivalent Grade

| Grade | UNS No | Old British | Euronorm | GOST | Japanese JIS | ||

| BS | En | No | AFNOR | ||||

| Inconel 600 | N06600 | NA 14 | NiCr15Fe | 2.4816 | NC 15 FE11M | МНЖМц 28-2,5-1,5 | NCF 600 |

ASTM B166 Inconel 600 Bolts Physical Properties

| Density | 8.47 g/cm3 |

| Melting Point | 1413 °C (2580 °F) |

| Tensile Strength | Psi – 95,000 , MPa – 655 |

| Yield Strength (0.2%Offset) | Psi – 45,000 , MPa – 310 |

| Elongation | 40 % |

Inconel 600 Nuts Prices

| Inconel Alloy 600 Fasteners Price List | Price Per Pcs. |

|---|---|

| Inconel Alloy 600 Screws price | USD $3.50 |

| Inconel UNS N06600 Nuts price | USD $1.35 |

| Inconel 600 Machine bolt price | USD $5.30 |

| Inconel Alloy 600 Allen bolt price | USD $5.15 |

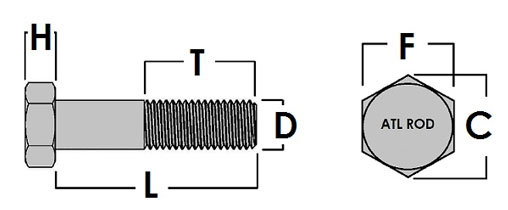

Alloy 600 Stud Bolts Dimension Chart

| Bolts Diameter | D | F | C | H | |||||

| Body Diameter | Width Across Flats | Width Across Corners | Height | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Grade N06600 Bolts and Nuts Weight

| Size (MM) | Weight per Metre | Size (UNC) | Weight per Mtr |

|---|---|---|---|

| M2 | 0.0187 | ||

| M2.5 | 0.030 | ||

| M3 | 0.044 | ||

| M3.5 | 0.060 | ||

| M4 | 0.078 | ||

| M5 | 0.124 | ||

| M6 | 0.177 | ¼” | 0.194 |

| M8 | 0.319 | 5/16” | 0.323 |

| M10 | 0.500 | 3/8” | 0.469 |

| 7/16” | 0.650 | ||

| M12 | 0.725 | ½” | 0.896 |

| M14 | 0.970 | 9/16” | 1.096 |

| M16 | 1.330 | 5/8” | 1.342 |

| M18 | 1.650 | ||

| M20 | 2.080 | ¾” | 2.021 |

| M22 | 2.540 | 7/8” | 2.756 |

| M24 | 3.000 | 1” | 3.638 |

| M27 | 3.850 | 1 1/8” | 4.545 |

| M30 | 4.750 | 1 ¼” | 5.718 |

| M33 | 5.900 | 1 3/8” | 6.842 |

| M36 | 6.900 | 1 ½” | 8.281 |

| M39 | 8.200 | 1 5/8” | 9.726 |

| M42 | 9.400 | 1 ¾” | 11.231 |

| M45 | 11.000 | 1 7/8” | 13.038 |

| M48 | 12.400 | 2 | 14.741 |

SB166 Inconel 600 Screws Grade Chart

| Hexagon Bolts / Set Screws | Stud Bolts | Hexagon Nuts | Socket Cap screws |

|---|---|---|---|

| DIN 931 | BS4882 | DIN 934 | DIN 912 |

| DIN 933 | DIN 976 | BS 1768 | DIN 6912 |

| BS 1768 | BS 1769 | DIN 7984 | |

| UNI 5731 | BS 1083 | ANSI B18.3 | |

| UNI 5739 | BS 3692 | ISO 4762 | |

| ISO 4014 | ISO 4032 | UNI 5931 | |

| ISO 4017 | ISO 4033 | BS 2470 | |

| BS 1769 | ANSI B18.2.2 | BS 4168 | |

| BS 3692 | |||

| ANSI B18.2.1 |

| Socket & Slotted Set Screws | Socket & Slotted Countersunk Screws | Studs | Washers |

|---|---|---|---|

| DIN 913 | DIN 963 | DIN 938 | DIN 125 |

| DIN 914 | DIN 7991 | DIN 939 | DIN 9021 |

| DIN 915 | BS 4168 | DIN 2510 | BS 4320 |

| DIN 916 | BS 1981 | BS 4439 | BS 3410 |

| DIN 551 | BS 483 | BS 2693 | |

| DIN 553 | BS 2470 | Spring Washers | |

| DIN 438 | DIN 127 | ||

| BS 4168 | BS 4464 | ||

| BS 1802 |

WERKSTOFF NR. 2.4816 Threaded Rod Uses

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Large Inventory of Alloy 600 Stud Bolts, Check Properties of Gost МНЖМц 28-2,5-1,5 Screws

Properties of 600 Alloy Socket Head Cap Screws

| Electrical Properties | |||

| Electrical Resistivity | 0.000103 ohm-cm | 0.000103 ohm-cm | |

| Magnetic Permeability | 1.01 | 1.01 | at 200 oersted (15.9 kA/m) |

| Curie Temperature | -194 °C | -317 °F | |

| Thermal Properties | |||

| CTE, linear 20°C | 13.3 µm/m-°C | 7.39 µin/in-°F | 20-100°C |

| Heat Capacity | 0.444 J/g-°C | 0.106 BTU/lb-°F | |

| Thermal Conductivity | 14.9 W/m-K | 103 BTU-in/hr-ft²-°F | |

| Melting Point | 1354 – 1413 °C | 2470 – 2580 °F | |

| Solidus | 1354 °C | 2470 °F | |

| Liquidus | 1413 °C | 2580 °F | |

Inconel Fasteners VS Monel Fasteners

Inconel 600 Fasteners

Inconel 600 is composed of nickel, chromium, iron and other elements. It offer service in both moderate and higher temperatures up to 2000 deg F. Check Chemical Composition in below table

| Element | Content (%) |

| Nickel, Ni | 72.0 min |

| Silicon, Si | .50 max |

| Carbon, C | .15 max |

| Sulphur, S | .015 max |

| Copper, Cu | .50 max |

| Iron, Fe | 6.0-10.0 |

| Manganese, Mn | 1.00 max |

Monel Fasteners

Monel fasteners are made from a nickel-copper alloy and exhibit high strength, toughness and good corrosion resistance over a wide temperature range. Monel 400 alloy has been used at temperatures up to 800°F-1000°F in sulfur-free oxidizing atmospheres.

| Monel K500 Fasteners, % | Nickel | Copper | Aluminum | Titanium | Carbon | Manganese | Iron | Sulfur | Silicon |

| ≥63.0 | 27.0-33.0 | 2.30-3.15 | 0.35-0.85 | ≤0.25 | ≤1.50 | ≤2.0 | ≤0.01 | ≤0.50 | |

| Monel 400 Fasteners, % | Nickel | Carbon | Manganese | Iron | Sulfur | Silicon | Copper | ||

| ≥63.0 | ≤0.30 | ≤2.0 | ≤2.50 | ≤0.024 | ≤0.50 | 28.0-34.0 |

Importers of 600 Alloy Socket Head Cap Screws and U Bolt Sizes

Alloy 600 Fasteners Sizes

| METRIC SIZES | ||

| Thread Size D (mm) | Hexagon Size S (mm) | Hexagon Size J (mm) |

| M 10 | 17 | 8 |

| M 12 | 19 | 10 |

| M 14 | 22 | 12 |

| M 16 | 24 | 14 |

| M 18 | 27 | 14 |

| M 20 | 30 | 17 |

| M 22 | 32 | 17 |

| M 24 | 36 | 19 |

| M 27 | 41 | 19 |

| M 30 | 46 | 22 |

| M 33 | 50 | 24 |

| M 36 | 55 | 27 |

| M 39 | 60 | 27 (30) |

| M 42 | 65 | 32 |

| M 45 | 70 | - |

| M 48 | 75 | 36 |

| M 52 | 80 | 36 |

| M 56 | 85 | 41 |

| M 60 | 90 | 46 |

| M 64 | 95 | 46 |

| M 68 | 100 | 50 |

| M 72 | 105 | 55 |

| M 76 | 110 | 60 |

| M 80 | 115 | 65 |

| M 85 | 120 | 70 |

| M 90 | 130 | 70 (75) |

| M 95 | 135 | - |

| M 100 | 145 | 85 |

| M 105 | 150 | - |

| M 110 | 155 | - |

| M 115 | 165 | - |

| M 120 | 170 | - |

| M 125 | 180 | - |

| M 130 | 185 | - |

| M 140 | 200 | - |

| M 150 | 210 | - |

| IMPERIAL SIZES | ||

| Thread Size D (inch) | Hexagon Size S * (inch) | Hexagon Size J (inch) |

| 5/8 | 1 1/16 | 1/2 |

| 3/4 | 1 1/4 | 5/8 |

| 7/8 | 1 7/16 | 3/4 |

| 1 | 1 5/8 | 3/4 |

| 1 1/8 | 1 13/16 | 7/8 |

| 1 1/4 | 2 | 7/8 |

| 1 3/8 | 2 3/16 | 1 |

| 1 1/2 | 2 3/8 | 1 |

| 1 5/8 | 2 9/16 | - |

| 1 3/4 | 2 3/4 | 1 1/4 |

| 1 7/8 | 2 15/16 | 1 3/8 |

| 2 | 3 1/8 | 1 5/8 |

| 2 1/4 | 3 1/2 | 1 3/4 |

| 2 1/2 | 3 7/8 | 1 7/8 |

| 2 3/4 | 4 1/4 | 2 |

| 3 | 4 5/8 | 2 1/4 |

| 3 1/4 | 5 | 2 1/4 |